Peak District Millstones

Gritstone has been worked into tools to grind grain for at least 2,000 years. The earliest evidence are querns : simple blunt cones and cylinders worked entirely by muscle power can be found at Wharncliffe near Stocksbridge. Querns (that is hand powered stones) with a more familiar wheel design comes from an early medieval dig at Blackwell near Buxton. The millstones which attract the attention of the visitor most often, however, are the stones designed for use by water, wind and steam mills. There are probably 1,500 of these scattered throughout the Peak, although approx 80% are within 2 kilometers of a line drawn from Moscar (map ref.: SK2388) to Fox House (SK264803) and on to Dobb Edge (SK2687150) in the grounds of Chatsworth. A few more are on Stanton Moor, scattered around Ashover and in the quarries between Little Eaton and Belper. In the early 20th century a significant number of stones were quarried at Darley Dale then exported for use in paper mills, but few are left today.

Dressed millstone grit millstone - Stainsby Mill 19th / early 20th century.

|

19th century millstone & delph - Wildmoorstones (Burbage)

|

Domed millstone, Froggat Edge

|

It is important to distinguish between:

grindstones, used to sharpen metal cutting tools etc. pushed against their edges and

edge runners - cylindrical stones mounted on an axle and used to crush a variety of materials and even foodstuffs as they rolled around a pivot.

A special type of grindstone that was quarried in large numbers in the late 19th and early 20th centuries were pulp stones. These were mostly exported to Canada and Scandinavia to be mounted in machines used to pulp timber for paper making. Grindstones were quarried from gritstone in Derbyshire, but such coarse grained material had limited uses; the main source for the grindstones used in the Sheffield cutlery and tool industries in the 18th and 19th centuries were quarries in the Rotherham area, which contained fine grained sandstones. Edge runners crushed materials such as lead ore, paint pigment, glass for recycling, cork (for linoleum) and apples for cider.

Gritstone millstones quarried for milling flour were termed "Peaks" by millers. Up to the 18th century, millers in England used millstones quarried from a single grit block. These were "Peaks", but finer grained stones were also imported from the Cologne (Koln) area in Germany, and these were termed "Cullen" stones. In the 18th century, composite stones, made up from blocks of chert in a cement matrix, were often used to grind the increasingly popular white flour. Composites needed re-cutting less often and were less prone to discolour the flour; they were termed "French" stones, although they were manufactured in England (there are records of the chert blocks being offered for sale in Derby), as well as France. Many popular books claim that "French" stones replaced Derbyshire "Greys" because they were cheaper; in fact chert composites were much more expensive, but produced whiter flour, lasted longer and needed less maintenance.

Although the final dressing of millstones is known in great detail (see web site listing ) the basic quarrying was ca rried out on a small scale and never fully documented. Masons were typically part-timers, (archaeologists call them "day workers") who farmed and quarried according to season. A man and boy could produce a pair of stones in a month. Many of what appear to be the oldest stones are domed on one side and are well away from the Edges - probably worked boulders. Quarrying of solid rock was carried out in "delphs" - embayments in the natural edge (cliff) 10 -20 metres across, best seen at Burbage (SK985810). Prior to the 19th century, when explosives started to be used, this would have involved hand drilling a hole, inserting long metal plates, and then driving a wedge between the plates to split the rock: the "plug and feathers" technique; the half holes created are still evident see

rried out on a small scale and never fully documented. Masons were typically part-timers, (archaeologists call them "day workers") who farmed and quarried according to season. A man and boy could produce a pair of stones in a month. Many of what appear to be the oldest stones are domed on one side and are well away from the Edges - probably worked boulders. Quarrying of solid rock was carried out in "delphs" - embayments in the natural edge (cliff) 10 -20 metres across, best seen at Burbage (SK985810). Prior to the 19th century, when explosives started to be used, this would have involved hand drilling a hole, inserting long metal plates, and then driving a wedge between the plates to split the rock: the "plug and feathers" technique; the half holes created are still evident see

rried out on a small scale and never fully documented. Masons were typically part-timers, (archaeologists call them "day workers") who farmed and quarried according to season. A man and boy could produce a pair of stones in a month. Many of what appear to be the oldest stones are domed on one side and are well away from the Edges - probably worked boulders. Quarrying of solid rock was carried out in "delphs" - embayments in the natural edge (cliff) 10 -20 metres across, best seen at Burbage (SK985810). Prior to the 19th century, when explosives started to be used, this would have involved hand drilling a hole, inserting long metal plates, and then driving a wedge between the plates to split the rock: the "plug and feathers" technique; the half holes created are still evident see

rried out on a small scale and never fully documented. Masons were typically part-timers, (archaeologists call them "day workers") who farmed and quarried according to season. A man and boy could produce a pair of stones in a month. Many of what appear to be the oldest stones are domed on one side and are well away from the Edges - probably worked boulders. Quarrying of solid rock was carried out in "delphs" - embayments in the natural edge (cliff) 10 -20 metres across, best seen at Burbage (SK985810). Prior to the 19th century, when explosives started to be used, this would have involved hand drilling a hole, inserting long metal plates, and then driving a wedge between the plates to split the rock: the "plug and feathers" technique; the half holes created are still evident see

It is not clear how millstones were sold to millers. Some millers, or their agents, undoubtedly came to Derbyshire and bought stones on the spot. Through the 18th century, however, great numbers of millstones were bought and sold by the corporation of King Lynn, as a means of ensuring the trading position of the port.

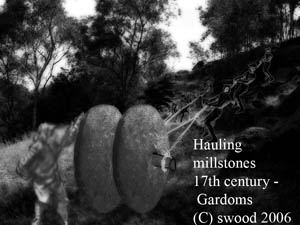

How were millstones transported? Even today, getting a block of stone weighing well over a ton from a steep slope is no casual task. When only muscle power was available, it is hard for the modern mind to comprehend how this could be a routine, but clearly it was. Stones were joined in pairs with a short wooden axle (listed in the probate inventory of a Dronfield merchant) and hauled up to the moorland at the top of the Edge. There, they were put on sledges, and hauled to a dock at Bawtry (now built over) on the River Idle, a tributary of the Trent. This enabled stones to then be shipped by water to Hull, and from Hull to Kings Lynn or other ports. Some stones were taken downhill and must have been transported down the Derwent valley.

There is a Flickr group dedicated to millstones

A millers view of millstones: Whitemill

|

Millstone timeline:

20th Century

|

"Peaks" have been used locally to grind animal feed and elsewhere for industrial uses such as grinding pigments, cork and glass (prior to recycling). Grit stones were exported routinely to wood pulp mills prior to 1914 , but the business reduced through the first half of the 20th century, with major interruptions for the two world wars. The last wood pulp stones were exported to Norway in the 1960's from Stoke Quarry at Grindleford. The limited use of gritstone for grinding metal (most natural grindstones were made from finer sandstones) ceased, because of legislation to reduce dangerous dusts in the period before WW1.

|

late 19th Century

|

Demand for flour milling declined rapidly. Steel or chilled iron (very hard, light coloured) rollers, driven by steam engines, transformed productivity in the milling industry following their introduction in the 1880's - not only could they process feedstock faster, they were easier to control, left no residue in the flour and were more suited to the hard grains imported from North America. Mills using millstones could not compete except when they were subsidised by great estates or found some niche market. On the other hand, industrial demand increased steadily. Many stones were exported to Canada and Scandinavia for use in pulping wood for paper making; a major operation existed in Darley Dale. Gritstones were also used for heavy metal grinding operations, such as the backs of 2 man saws, and for pulverising materials, such as tree bark for tanning, cork for lino or cocoa beans for chocolate.

|

Mid 19th Century

|

Demand rose as industries such as glass and paint manufacture used Peaks to grind hard materials. Animal feed was often ground in local wind & water mills using Peaks. Hard grain (high protein, and so good for bread making) imported from North America was found to be difficult to mill using millstones, which were worn quickly by the hard grains. A crushing stone still exists on Totley Moor, close to Moss Road, almost certainly used to crush locally mined ganister (fossiled soil found under coal seams) which was used to make bricks that would withstand the high temperatures need to make refactory steel.

|

Early 19th Century

|

The general economic depression which followed the end of the Napoleonic wars, along with the resumption of imports of flour and stones from Europe led to a collapse in the grit millstone trade. Millstones were also used before and after this period as edge runners for purposes as varied as crushing lead ore prior to smelting and extracting the juice from cider apples. A local variant produced on the west side of the Peak District were "Mow Cop" stones: gritstone composites made with sections quarried at Mow Cop and used in nearby mills. Click here to see images The general economic depression which followed the end of the Napoleonic wars, along with the resumption of imports of flour and stones from Europe led to a collapse in the grit millstone trade. Millstones were also used before and after this period as edge runners for purposes as varied as crushing lead ore prior to smelting and extracting the juice from cider apples. A local variant produced on the west side of the Peak District were "Mow Cop" stones: gritstone composites made with sections quarried at Mow Cop and used in nearby mills. Click here to see images |

18th Century

|

A fashion for white bread reduced demand milled by gritstone

stones. Composite stones, using pieces of chert embedded in a hard cement, were preferred because, in spite of being much more costly, they produced a whiter flour (believed to be less likely to be adulterated) and were slower to wear. Composite stones were known as "French" stones because the original (and best) composites were assembled using blocks of chert quarried near Paris. They were assembled in Derby and London, but no doubt their makers were happy to let foreigners take the blame for the reduced demand for traditional millstones. stones. Composite stones, using pieces of chert embedded in a hard cement, were preferred because, in spite of being much more costly, they produced a whiter flour (believed to be less likely to be adulterated) and were slower to wear. Composite stones were known as "French" stones because the original (and best) composites were assembled using blocks of chert quarried near Paris. They were assembled in Derby and London, but no doubt their makers were happy to let foreigners take the blame for the reduced demand for traditional millstones. |

Pre 18th Century

|

Peak stones were traded nationally, and had few competitors. They were typically hauled to Bawtry by sled and wagon, then transferred to barges or ships on the River Idle. They were often landed and re-shipped at Hull. A key destination was Kings Lynn, where the Corporation acted as a broker or wholesaler, especially at the time of the February "mart" (fair).

|

|

|

|

Abandoned pulp stones below Surprise View - probably late 19th century. A casual count found 154. NB These are not millstones, in spite of the claims of dozens of books!

|

Edge runner used to crush lead ore at the Odin Mine, Castleton - mid 19th century

|

Beveled millstone (unique design!), Stainsby Mill, nr Hardwick Hall. Operated until the early 20th century.

|

Copyright @ 2006 Stephen N.Wood. All rights reserved.

This is a Web Counter

This page has been accessed